Certification and Standards

- EU machinery directive (MD – 2006/42/EC)

- EMCD directive (2014/30/EU) by using requirements in the harmonized standard SS-EN 61326-1:2013

- Low Voltage Directive 2014/35/EU (LVD) requirements of harmonized standard: SS-EN61010-1(Ed3):2011

- RoHS directive (2011/65/EU)

- IP65 certified according to EN 60529:1991 + A1:2000 + A2:2013

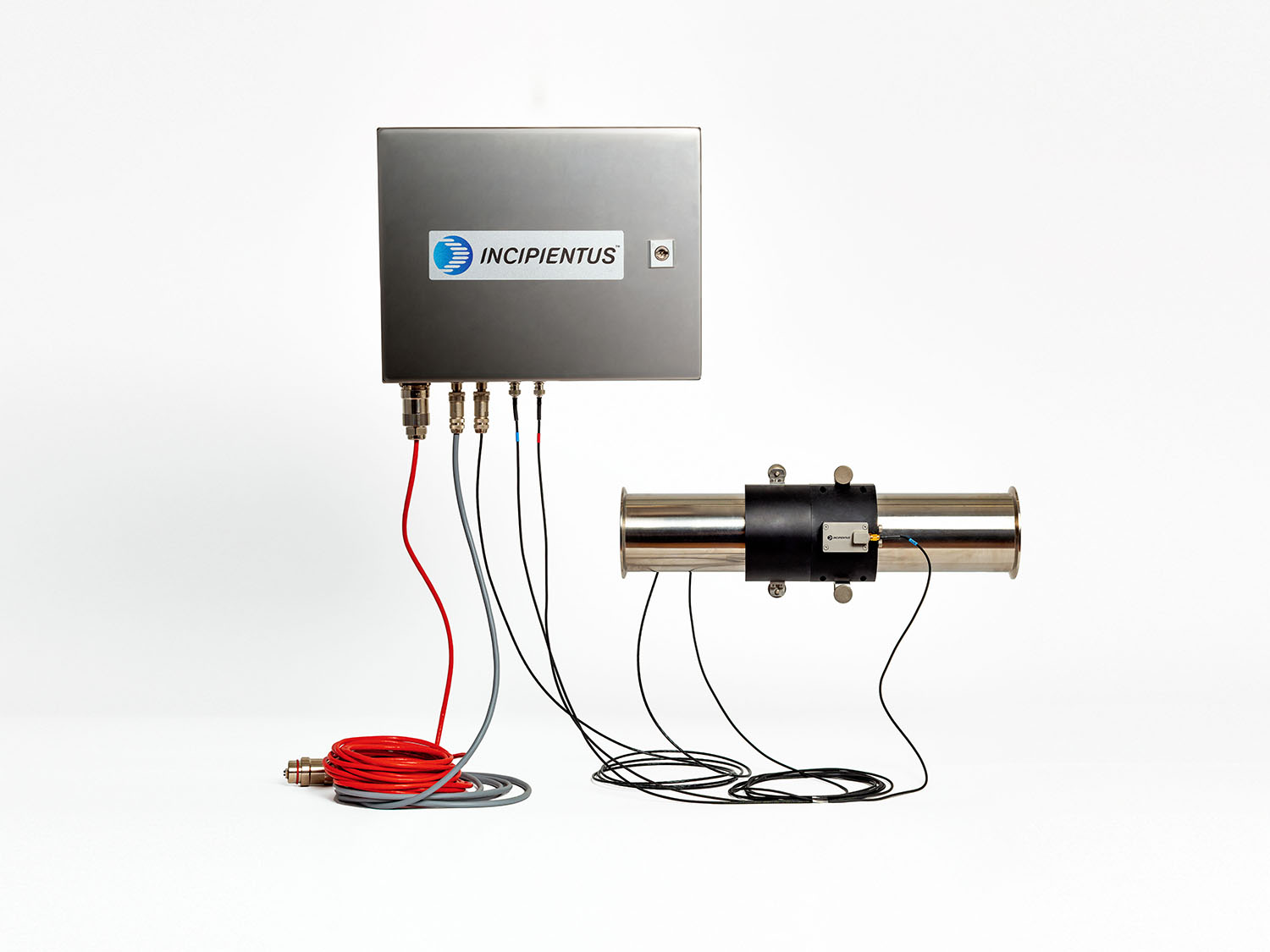

Process monitoring and quality control (ILP)

Our ILP series offers the most advanced touch-free industrial inline rheology measurements system for the global liquids processing industry. Designed for continuous process monitoring and quality control of industrial liquids in production plant environments. It delivers continuous critical and unique process data and product information during manufacturing for improved production efficiency and improved quality process control. The ILP provides more multi-point rheology data than competing techniques and is designed to replace time-consuming and operator dependent rheology testing in the laboratory with in-line and in real-time quality and process control. The ILP series is the essential and leading industrial inline rheometer for the liquids global processing industry.

Benefits and Capabilities

- Delivers continuous inline rheology data during manufacturing

- Allows real time product release through inline quality control

- Reduce wastage and reworks

- Improved quality control – rapid effective corrective actions

- Optimize production processes and improve product formulation

- Provide information to enhance process design

- Deep insights

- Touch-free and non-intrusive

- Industry 4.0 ready

- In-line, real-time, and continuous measuring and characterization

Get in touch

Johan Wiklund

Sales